Train Track

Update: The future is 3D

printing

8

February 2014

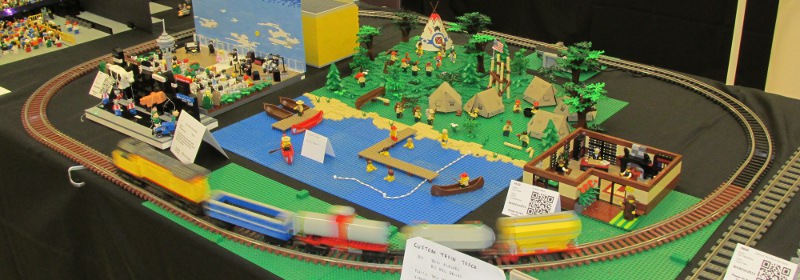

Over the last year many iterations of track have been tested.

In

October 2013 an entire loop of track was shown at BrickCon in Seattle

Washington (see below) and ran very well (using a stock 9v train

controller).

Moving forward Big Ben Bricks has no plans to develop tooling and

injection mold train track for LEGO trains. Instead, the

future for train track is with 3D

printing. 3D

printing is a way to 'print' your own plastic

parts based on a digital 3D design. 3D

printing technology

is quickly becoming very accessible in terms of cost and ease of use.

Further, the quality of print is quickly improving and the

cost

of the plastic is dropping as well - currently about $1 in plastic to

print one piece of track.

Only with 3D printing will it be possible to create the wide range of

pieces LEGO train builders want at reasonable prices.

With this strategy in mind, two types of track have been tested.

Metal rail with plastic ties and all plastic track. Please

see below for more information.

(click on images for larger, hi-resolution views)

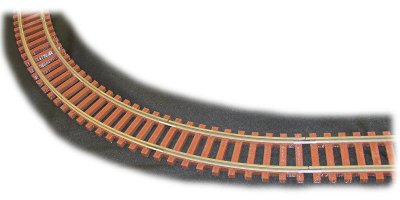

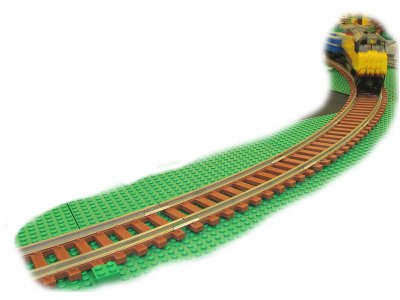

Sample oval of metal track at BrickCon in Seattle, Washington -

October 2013.

Metal rail with plastic

ties

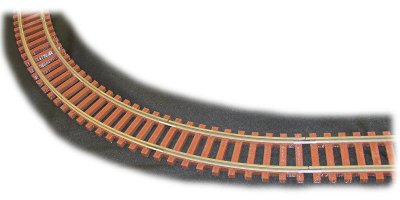

For metal rail, code 250 Nickel-Silver rail and rail joiners are bonded

to plastic sections of ties printed on a 3D printer. This

provides an excellent running surface, excellent

conductivity of the rail, good corrosion resistance and excellent

conductivity between sections of rail.

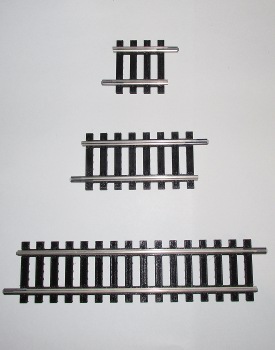

To achieve the layout shown above sections of track were made in three

lengths

of straights and three different curves.

72 stud radius curve

104 stud radius curve

3 straights (8 studs, 16 studs and 32 studs)

3 curves (104 stud radius -11.25 degrees (two shown, connected

together), 72 stud

radius-22.5 degrees and 56 stud radius-22.5 degrees)

(Standard

LEGO curve shown for comparison)

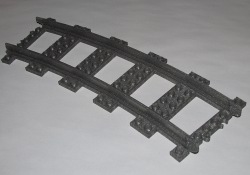

Close up detail of straight track

The metal rail on the curves is pre-formed with a simple rail bending

jig and cut to length. The plastic ties are the shaped as two 1x8

plates stacked on top of one another. The ties are offset from

the standard grid to allow full symmetry of the part. The code

250 rail is nearly identical in size to standard LEGO rail. The

precision of the 3D print is sufficient to allow a full 32 stud long

straight section to provide adequate 'clutch' power on LEGO baseplates.

All plastic track

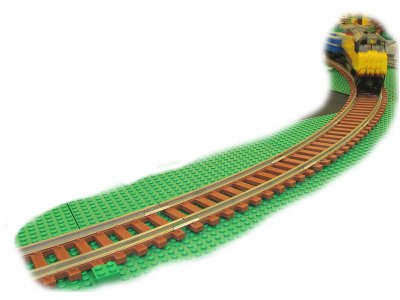

For those preferring battery powered trains, all plastic track

is

achievable too.

Sample pieces were printed in a metallic gray plastic.

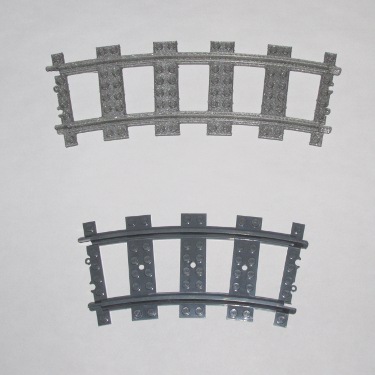

Top: 56 stud radius, 22.5 degree curve - 3D printed track

Bottom: Standard LEGO curve for comparison

Close up of all plastic curve.

3D printed curve connected to two standard LEGO curves.

All plastic track printed well and provided a rolling surface

comparable to standard, LEGO track. The very fine detail in

the track joints is a challenge for 3D Printing, but in testing, while

the joint was found to be a bit stiff, was still acceptable. The

stiffness is mostly the result of using PLA plastic which is more

rigid then ABS plastic. 3D printing is ABS is possible, but PLA

is a bit easier to work with.

Questions and Answers:

Question: Will Big Ben Bricks

sell 3D printed track?

Answer: No. While the

technology is advancing quickly, 3D

printing is rather labor intensive. Others may be

interested in printing track with their own 3D printers.

Question: Will Big Ben

Bricks make 3D designs suitable for 3D

printing available for others to use?

Answer: Provided there is

enough interest, 3D designs will be

provided for a nominal fee. For those that would like a

sample 3D

model, please email with a

request.

Question: What 3D Printer did you use?

Answer: All track shown here

are printed with PLA plastic using a MakerGear M2 printer. Fully

assembled printers can be purchased for less then $2000.

Question: Is 3D printing easy and trouble free?

Answer: It is getting easier

and more trouble free every year, but currently a little tinkering is

typically required to make everything work just right.